In the food industry, ensuring the safety of packaging materials is paramount to maintaining the quality and safety of products. Round plastic pails are a popular choice for storing and transporting food items, but it’s crucial that they meet FDA, EU, and local food safety standards. In this article, we will discuss how businesses can ensure their round plastic pails comply with these essential regulations.

1. Understanding FDA, EU, and Local Food Safety Standards

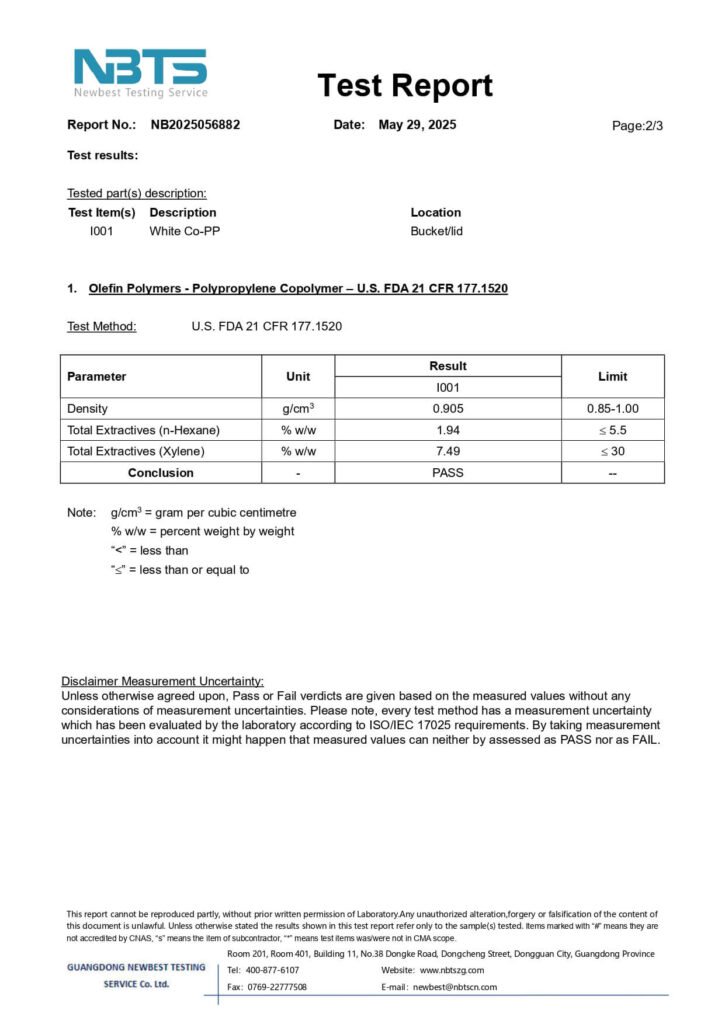

FDA Standards (USA): The FDA requires packaging materials that come in contact with food to be made from safe, non-toxic materials. For plastic pails, the material must comply with FDA regulations under 21 CFR Part 177. The plastic must not leach harmful chemicals into food, and migration testing is often required.

EU Regulations: The EU has its own set of food safety standards under Regulation (EC) No. 1935/2004 and EU Directive 10/2011. These regulations ensure that plastic materials used in food packaging are safe and do not transfer harmful substances to the food.

Local Food Safety Requirements: Local regulations, such as those in China or Japan, also impose standards on plastic containers used for food packaging. These standards can vary, so it’s essential for businesses to ensure their pails meet the specific requirements of the regions they serve.

2. Choosing the Right Material: Food-Grade Plastics

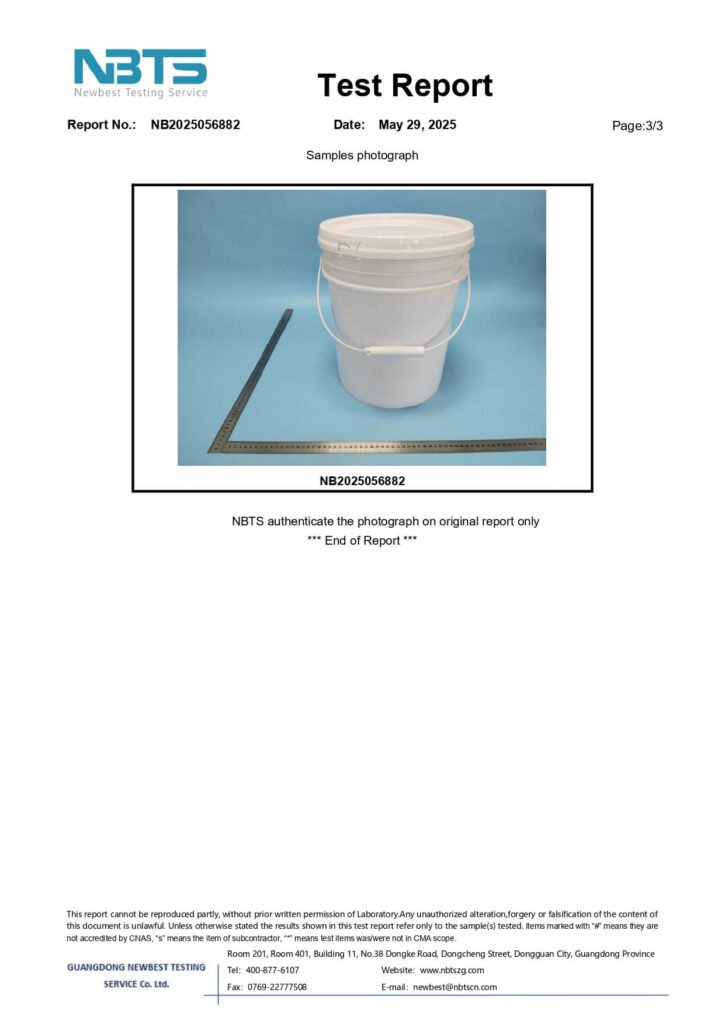

To meet FDA, EU, and local standards, round plastic pails must be made from food-grade plastics, such as high-density polyethylene (HDPE) or polypropylene (PP). These materials are non-toxic, BPA-free, and highly resistant to chemicals, making them safe for direct contact with food.

When selecting a plastic material for food-grade pails, businesses must ensure the material complies with the relevant safety standards. HDPE is commonly used because of its strength, moisture resistance, and low migration levels. It also meets FDA requirements for food contact materials.

3. Manufacturing Processes and Food Safety Compliance

The process used to manufacture round plastic pails is just as important as the materials. Injection molding and rotational molding are common methods used to produce plastic pails, and both must adhere to strict quality control standards to prevent contamination.

To ensure compliance, manufacturers must maintain a clean production environment and avoid any contact with non-food-safe materials during production. Using third-party certifications from recognized testing organizations can help verify that the pails meet FDA and EU food safety requirements.

4. Certification and Testing for Compliance

Meeting food safety standards requires rigorous testing. The following tests are essential:

- Migration Testing: This test assesses whether harmful chemicals or substances migrate from the plastic material into food. Migration testing is required by both the FDA and EU for materials used in direct contact with food.

- Toxicity Testing: Ensures that no toxic substances, such as BPA or phthalates, leach from the plastic pail into the food.

Certification Marks: Obtaining certifications like the FDA approval mark for food-grade plastics or EU food contact compliance certificates is essential for legal compliance and consumer trust.

5. Labeling and Traceability

Proper labeling is key to food safety compliance. Round plastic pails should be clearly marked with relevant symbols, such as food-safe symbols and recycling logos. Additionally, batch numbers or product codes should be included for traceability purposes, allowing manufacturers to track the origin and distribution of each batch of product.

6. Best Practices for Handling and Storing Food-Grade Pails

To maintain food safety, businesses must also ensure that round plastic pails are properly handled and stored:

- Storage Conditions: Food-grade pails should be stored in clean, dry environments to prevent contamination. They should not be exposed to direct sunlight, excessive heat, or moisture, as this can degrade the material over time.

- Sanitization: Regular cleaning and sanitization of plastic pails are essential. The smooth, non-porous surface of food-grade plastics makes cleaning easier and helps prevent bacterial buildup.

- Handling: Workers should follow proper handling procedures to avoid contamination when transferring food into or out of plastic pails. Using gloves and ensuring that handling equipment is sanitized can further reduce risks.

Conclusion

Ensuring that round plastic pails meet FDA, EU, and local food safety standards is critical for maintaining food safety and protecting consumer health. By selecting food-grade materials, following proper manufacturing processes, obtaining certifications, and maintaining clean storage and handling practices, businesses can confidently use plastic pails to store and transport food products. These measures not only guarantee compliance but also foster trust in the brand and the products it delivers.