About Us

Enlightening Plast Industry Co., Limited was founded in 2000. Is a leading manufacturer specializing in the production of high-quality plastic buckets. Our headquarters are located in Qingdao, China, with advanced manufacturing facilities in Guangdong and Jiangsu, covering a total area of 90,000 square meters.

25 Years

Experience

100+

Countries and Regions

400+

Employees

600+

Products

Our Factory

Raw Material Workshop

We purchase 100% new HDPE and PP materials from PetroChina and have established a dedicated raw material storage and pretreatment workshop to ensure that all inputs are in optimal condition before entering the production process. This meticulous control guarantees that each HDPE bucket and PP bucket we produce meets the highest standards of quality.

All raw materials are strictly screened to ensure that the buckets have high strength, impact resistance, anti-aging, and other excellent properties.

Mould Warehouse

The precision of the mold determines the quality of the product. Our mold workshop is equipped with an advanced CNC machining center, CNC milling machine, EDM forming machine, and other equipment to ensure that the mold manufacturing accuracy reaches the micron level.

We have more than 600 bucket molds of different specifications and models.

Our engineering team has extensive experience and can customize customized molds according to customer needs, which provides a strong guarantee for efficient mass production.

Production Workshop

We have 20 fully automatic production lines to ensure that we can meet the manufacturing needs of large orders.

All intelligent monitoring systems are used in the production process to achieve data management and ensure the consistency and stability of each batch of products.

In addition, the robot arms work together, greatly improving production efficiency while reducing labor costs.

Sample Room

The sample room has more than 1000 products, covering various specifications and different models. And we are ready to provide you with free samples for you to choose and test, to ensure that the product fully meets your needs.

Quality Inspection Workshop

Quality is the life of an enterprise. We have established a strict IQC (incoming material inspection), IPQC (process inspection), and FQC (finished product inspection) system. High standards of testing are performed at every stage.

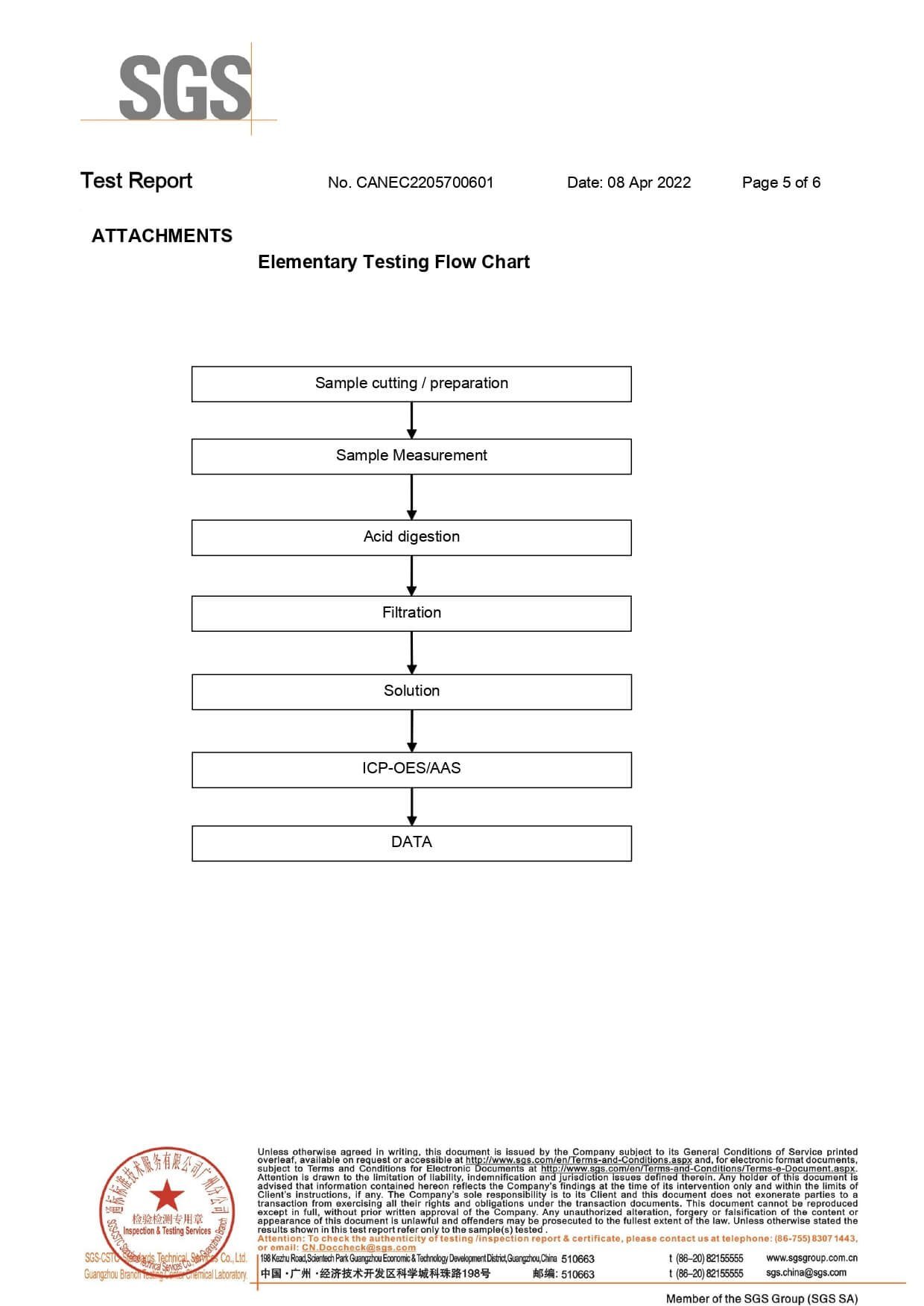

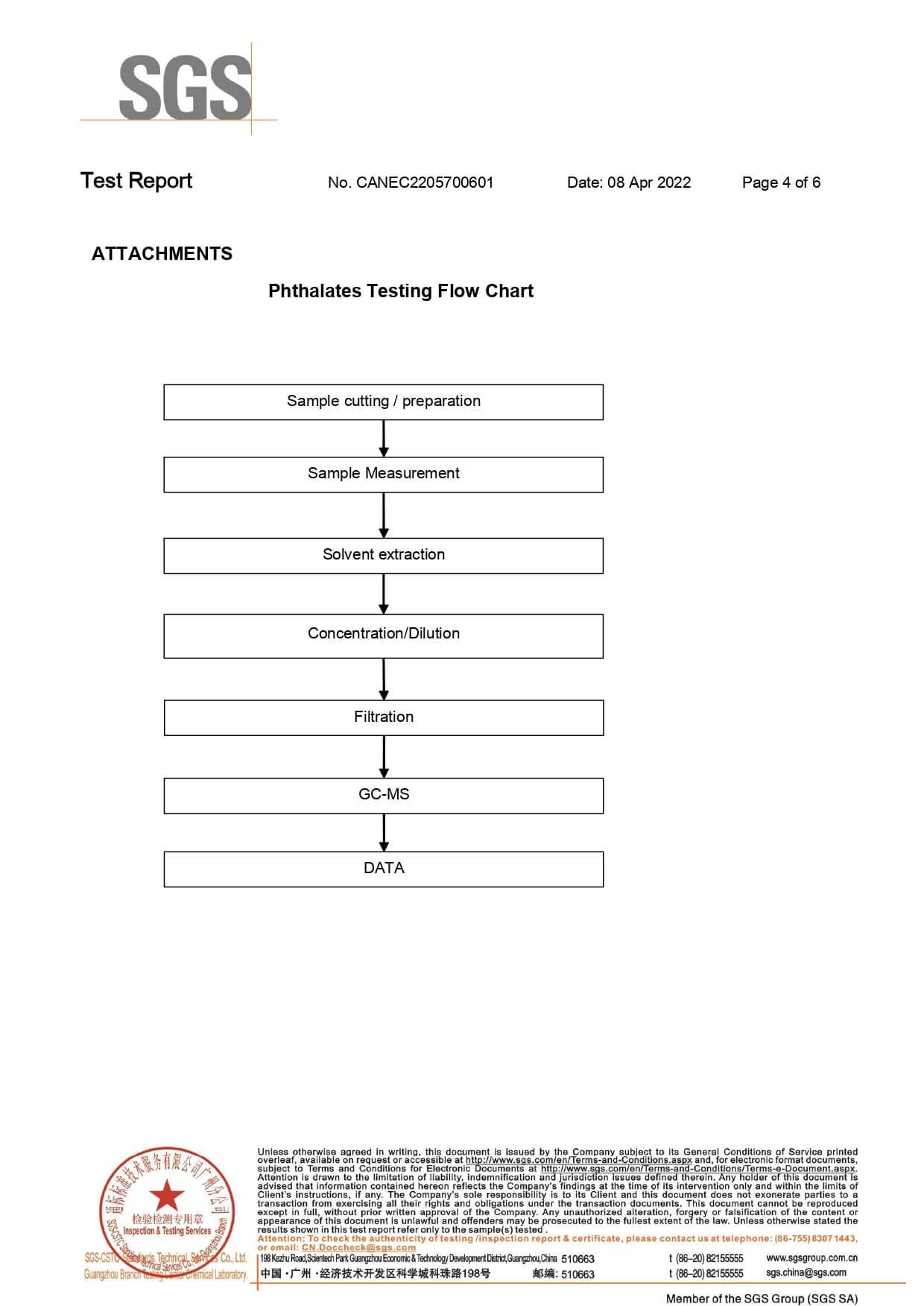

Process: Sampling → Dimension measurement (caliper, projector) → Physical performance test (impact, temperature resistance) → Chemical performance test (corrosion resistance) → Issue report.

Product Warehouse

Our warehouse adopts an intelligent storage system to ensure clear product classification, real-time inventory monitoring, and improved shipping efficiency.

Quality Certification

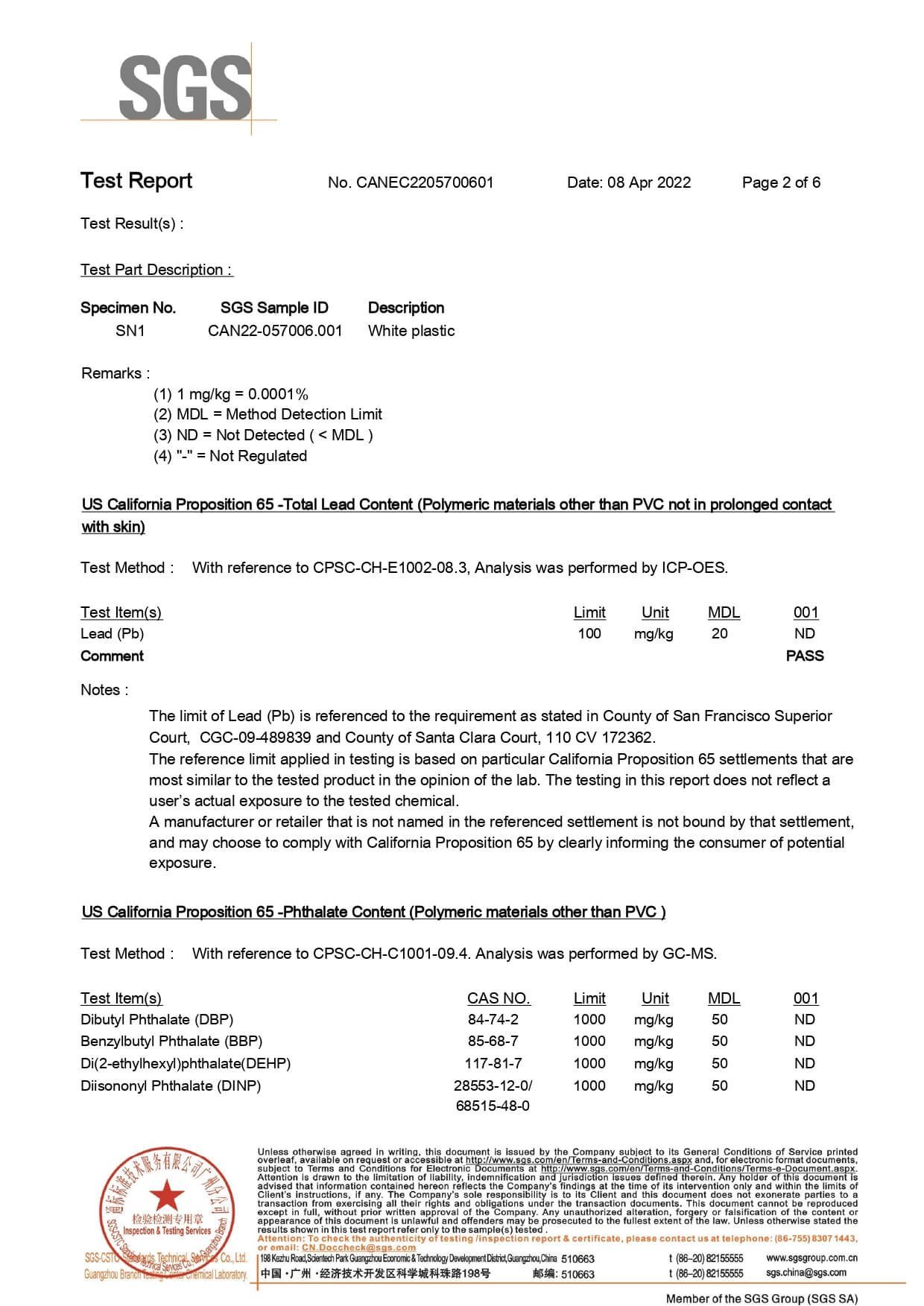

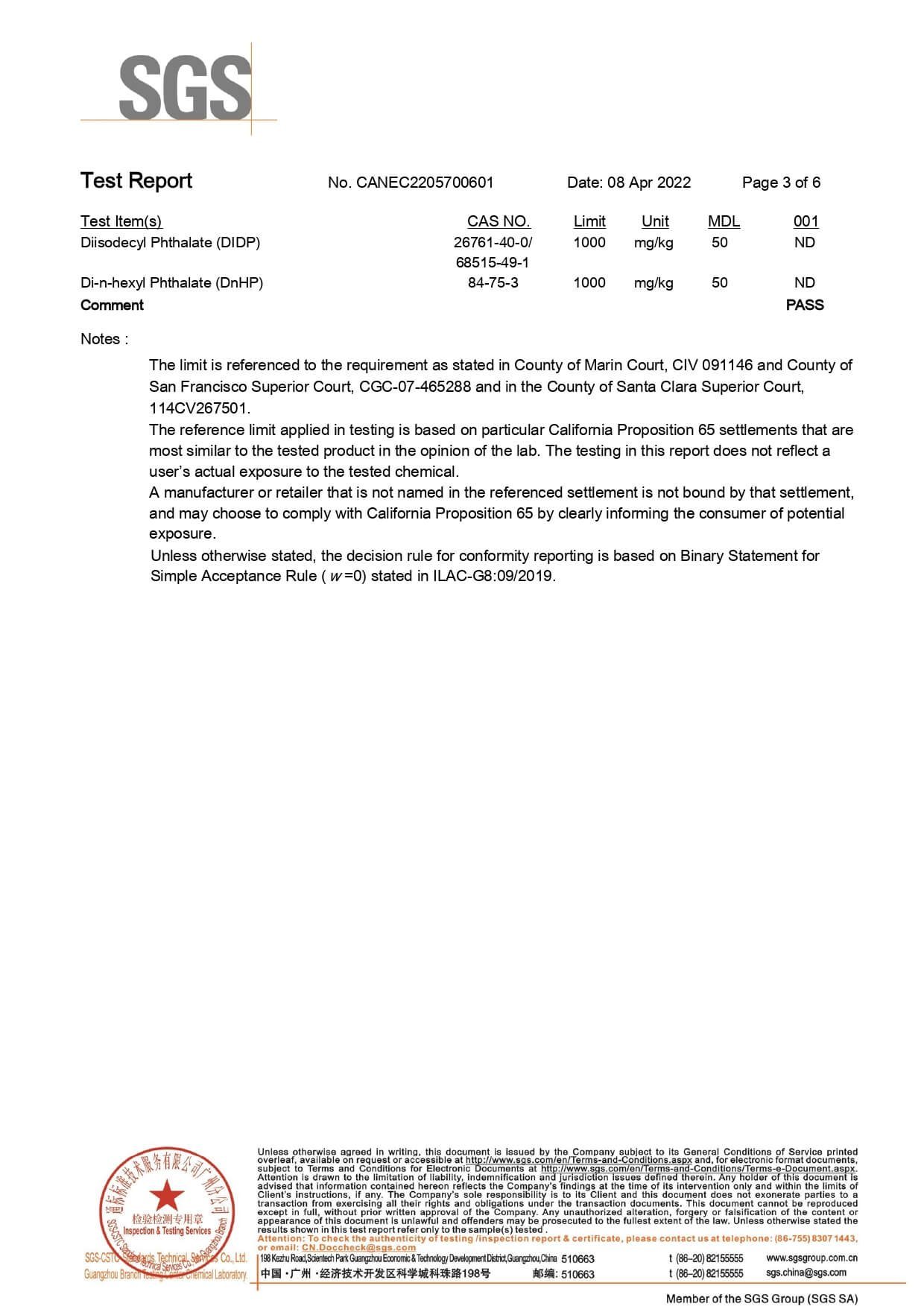

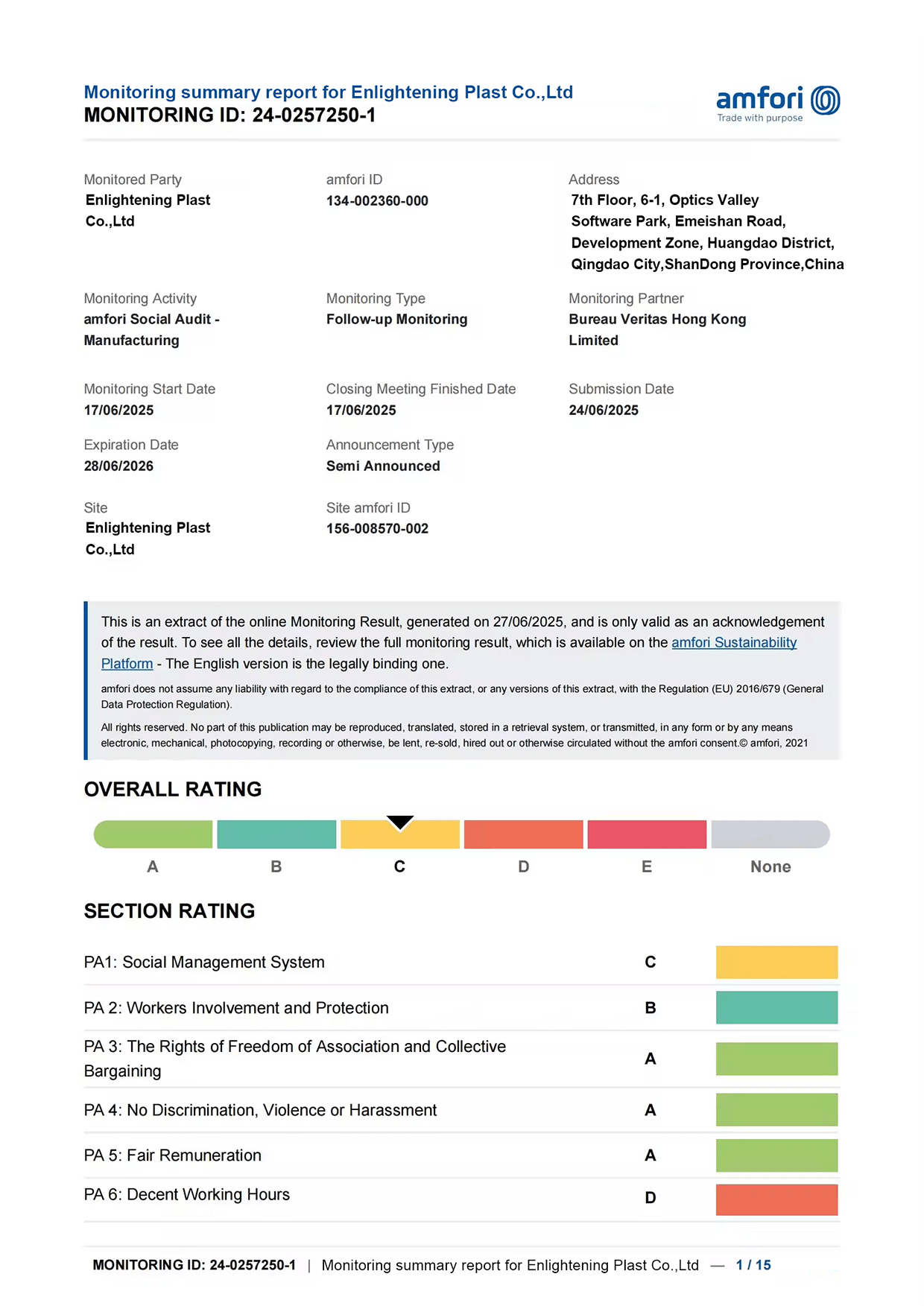

We strictly follow the ISO9001 management system and have obtained UN certification, CTT certification, EN-840, and FDA certification.

Quality Test

To test the quality of plastic buckets, we conducted stacking load capacity tests, drop tests, air tightness, and sealing tests.

Global 500+ Brand Cooperation

Partner with a distinguished leader specializing in fostering alliances with Global 500+ brands to drive mutual growth and innovation.

Our Services

Pre-Sales Service

Professional consultation, customization service, sample provision

After-Sales Service

order tracking, quality inspection, packaging design

After-Sales Service

3-year warranty, quick response

Our Advantages

Unlock premium quality, innovative solutions, and personalized service. Experience efficiency redefined through our expertise-driven approach tailored to exceed expectations

Expert Answers

We will provide you with 24/7 professional services to ensure that any questions you want to know can be answered at any time.

Super long warranty

Our products have different types, and the highest warranty can be up to 3 years to protect your rights.