Plastic buckets are widely used in industry, agriculture and daily life because of their lightness, durability and low cost. They are often used to store chemicals such as acids, alkalis, solvents, greases, pesticides, etc. Thoroughly cleaning these chemical residues not only ensures safety and environmental protection but also prolongs the service life of the plastic pails. However, cleaning chemical residues is far more complicated than ordinary dirt because of their diverse nature, possible penetration into plastics, and high safety risks.

This article aims to provide comprehensive and practical cleaning steps and precautions, following the core principles of “safety first, understanding residues, choosing appropriate methods, thorough rinsing, and proper disposal of waste liquids”.

Understanding plastic buckets and chemicals

Bucket Materials and Their Properties

HDPE Bucket(High-Density Polyethylene): Strong resistance to most acids, alkalis, and solvents. The most common material for chemical buckets.

PP Bucket(Polypropylene): Higher temperature tolerance (up to 100°C+), also acid- and alkali-resistant, suitable for hot-fill or steam cleaning.

Plastics are not completely inert. Organic solvents and strong oxidizers may cause swelling, softening, or absorption. Long-term exposure makes cleaning more difficult.

Classification of chemical substances:

- Acids and alkalis, such as sulfuric acid and sodium hydroxide, are corrosive and need to be neutralized.

- Solvents, such as alcohol, toluene, and acetone, are volatile and need to be fireproof and explosion-proof.

- Oils and fats, such as lubricating oils, are highly viscous and require special degreasing agents.

- Agrochemicals, such as pesticides and herbicides, are highly toxic and require reference to the Safety Data Sheet (SDS).

- Special chemicals, such as resins and glues, have strong adhesion and are difficult to clean.

Difficulty and risks of cleaning: Volatile substances bring inhalation risks; toxic substances must be strictly prevented from contact; mixing incompatible substances may produce highly toxic gases (such as bleach + acidic detergent = chlorine) or violent reactions.

Risk assessment before cleaning:

Before cleaning, confirm the toxicity, volatility and corrosiveness of the chemical and consult the Safety Data Sheet (SDS) to understand the cleaning requirements and risks.

Key preparations before cleaning

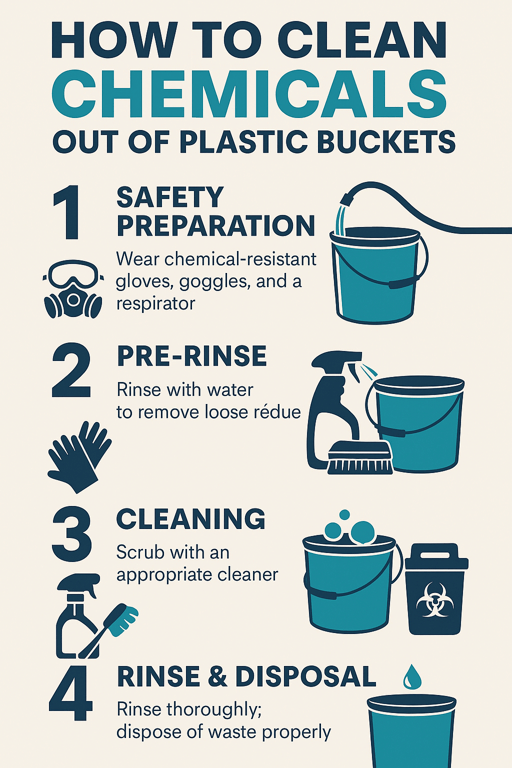

1. Safety first – Personal protective equipment (PPE)

Chemical-resistant gloves, goggles/masks, protective clothing and respiratory protective equipment (such as masks or gas masks) must be worn. PPE is a lifeline and must not be omitted.

2. Work environment preparation

Choose a well-ventilated area away from fire sources and crowds, preferably outdoors. Prepare absorbent cotton, leak-proof trays and emergency equipment (such as eyewash, fire extinguisher).

3. Tool and material preparation

- Cleaning agents: water, special cleaning agents, solvents, baking soda, activated carbon, etc.

- Tools: long-handled brush, high-pressure water gun, spray bottle, disposable wiping cloth.

- Auxiliary materials: measuring cup, label, waste liquid collection container.

Cleaning Methods by Residue Type

1. How to Neutralize Chemical Barrels

If your plastic bucket stores acidic or alkaline substances:

- Use baking soda (alkaline) to neutralize acid, or citric acid (mild acid) to neutralize alkali.

- Mix slowly in water, pour into the bucket, and stir.

- Use pH strips to monitor until levels are between 6.5–7.5.

- Rinse thoroughly with water.

Knowing how to neutralize chemical barrels is essential before using solvents or mechanical cleaning methods.

2. Remove Acid Residue from Plastic Pails

For acid residues:

- Rinse with large amounts of clean water.

- Neutralize with a weak alkaline solution like sodium bicarbonate (baking soda).

- Scrub with a brush and rinse 3–5 times until neutral.

Always wear gloves and goggles when handling corrosive substances.

3. Solvent Cleaning for Oils & Adhesives

When dealing with oils, lubricants, or paint:

- Use compatible solvents like ethanol or isopropyl alcohol.

- Avoid aggressive solvents (e.g., toluene) that may damage plastic.

- Add solvent, seal the lid, and shake or roll the bucket.

- Ventilate the area due to flammable vapors.

4. How to Clean Pesticides from Buckets

Pesticides pose serious risks and require thorough handling:

- Refer to the SDS for exact decontamination protocols.

- Use agrochemical-specific detergents and triple rinse with water.

- Use drum liners in the future to prevent chemical absorption.

Understanding how to clean pesticide from buckets ensures you stay compliant with environmental and workplace regulations.

5. Steam or Pressure Cleaning (for heavy residues)

- Use a steam cleaner or high-pressure washer for stubborn residues.

- Ensure your bucket material tolerates heat (HDPE < 80°C, PP > 100°C).

- Use this method for industrial settings where manual cleaning is inefficient.

Post-cleaning treatment and acceptance

- Drying

Turn the pail upside down to drain, air dry, or blow dry with oil-free compressed air.

- Inspection and acceptance

Visually check whether the inner wall is smooth and free of residue.

Smell to check whether there is any odor.

Wipe with a white cloth or test with pH test paper, and fill with water to stand to detect contamination if necessary.

- Sealing and storage

After cleaning and drying, cover the bucket tightly and store it in a cool and ventilated place.

Environmental and safety precautions

Waste liquid treatment: All waste liquids should be sent to professional facilities for treatment and comply with environmental regulations.

Safe operation: Avoid mixing chemicals and ensure good ventilation.

Reuse of barrels: Reuse after confirming that they are thoroughly cleaned; otherwise, send them to the recycling station.

Need Wholesale Plastic Buckets for Industrial Chemicals?

Enlightening Plast is a professional manufacturer of HDPE and PP chemical-grade plastic buckets, available in 5-gallon, 20L, and custom sizes. We support:

- OEM/ODM branding

- Food-grade and chemical-grade certifications

- Fast delivery and international logistics support

📦 Explore our full range: View Chemical Buckets Product Page

📧 Get a free quote today: Steve@cnbuckets.com

Conclusion

Cleaning chemical residues in a plastic bucket is a complex but necessary task, the core of which is safety, understanding, methods, thoroughness and responsibility. By understanding the properties of chemical substances, choosing appropriate cleaning methods, and strictly implementing safety and environmental protection regulations, residues can be effectively removed to ensure safe reuse of plastic buckets.

For uncertain, high-risk, or large-scale cleaning tasks, seeking professional cleaning services is the safest and most reliable choice. Proper disposal of all waste liquids is the bottom line for protecting the environment and public safety, and should not be ignored.

FAQs About Cleaning Chemicals Out of Plastic Buckets

Q1: Can I reuse a plastic bucket that stored pesticides?

You can reuse it only if you know how to clean pesticides from buckets properly. This includes triple rinsing with specialized agrochemical cleaners, thorough drying, and ensuring no residual toxicity per SDS guidelines. Avoid using the bucket for food or drinking water.

Q2: What’s the best way to remove acid residue from plastic pails?

To remove acid residue from plastic pails, neutralize the acid using a mild base like baking soda. Monitor the pH and rinse thoroughly with clean water 3–5 times. Always wear full PPE during this process.

Q3: How do I neutralize a chemical bucket before disposal or reuse?

Understanding how to neutralize chemical barrels is key to safe handling. Use weak acids or bases depending on the original contents, stir the solution inside the bucket, and test with pH strips until the pH reaches neutral (6.5–7.5). Rinse and dry afterward.

Q4: Are HDPE buckets safe for cleaning and reuse after chemical storage?

Yes—cleaning chemicals from HDPE buckets is standard industrial practice due to HDPE’s strong chemical resistance. However, only reuse them after confirming the bucket is intact, thoroughly cleaned, and labeled for its new contents. If you’re looking for certified chemical-resistant HDPE buckets, check out our full product line here:

🔗 Browse Chemical HDPE Buckets

Q5: What are some industrial bucket cleaning safety tips I should follow?

Follow these industrial bucket cleaning safety tips:

- Collect and dispose of rinse water according to local regulations

- Wear PPE (gloves, goggles, respirator)

- Work in ventilated or outdoor areas

- Avoid mixing incompatible chemicals (e.g., acids + bleach)