Screen printing on plastic buckets is an essential process in the packaging industry, allowing businesses to brand their products effectively and provide important information to consumers. Whether you’re manufacturing food containers, industrial supplies, or promotional items, understanding the various printing methods available can help you achieve high-quality, durable prints that enhance your product’s appeal and functionality.

Understanding Plastic Bucket Materials

Before diving into printing methods, it’s important to understand the materials commonly used for plastic buckets. The two most prevalent types are:

HDPE (High-Density Polyethylene)

HDPE buckets are opaque, sturdy, and resistant to chemicals. They’re commonly used for industrial applications, household products, and bulk storage. The surface of HDPE requires proper treatment for optimal print adhesion.

PP (Polypropylene)

PP buckets can be transparent or opaque and are often used for food packaging. They offer excellent heat resistance and flexibility. PP surfaces generally accept printing well, especially when properly prepared.

Screen Printing

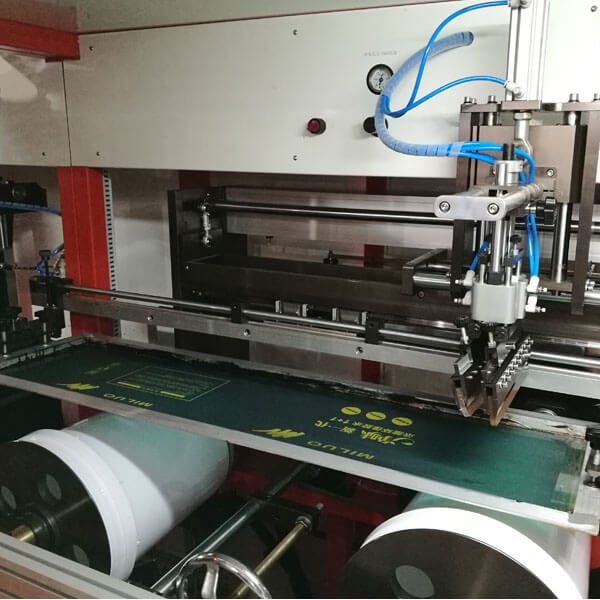

Screen printing (also known as silk screening) is the most widely used method for printing on plastic buckets, especially for medium to large production runs. This technique uses a mesh screen to transfer ink onto the bucket surface, creating vibrant, durable prints with excellent color opacity.

Process Overview:

- Design Preparation: Create your design in vector format and separate it into individual spot colors. Each color requires its own screen, so plan your color palette carefully. Convert gradients to halftones if necessary.

- Screen Creation: Coat a fine mesh screen (typically 110-230 mesh count for plastic) with light-sensitive emulsion. Place your film positive on the screen and expose it to UV light. Wash away the unexposed emulsion to create your printing stencil.

- Surface Treatment: Clean buckets thoroughly to remove dust, oils, and contaminants. Apply corona or flame treatment to increase surface energy and improve ink wettability. Test treated surfaces within 24-48 hours for optimal adhesion.

- Ink Application: Place the screen on the bucket and use a squeegee to push ink through the mesh openings onto the surface.

- Curing: Dry printed buckets in a conveyor dryer or oven at temperatures specified by the ink manufacturer (typically 150-180°C for plastisol, UV cure for UV inks). Ensure complete cure for maximum durability and adhesion.

- Quality Check: Check each bucket for print registration, color accuracy, coverage, and adhesion. Perform tape tests and scratch tests on sample pieces. Inspect for defects like pinholes, smudges, or incomplete coverage.

Technical Specifications

| Specification | Details |

| Ideal Production Volume | 1,000 – 100,000+ units per run |

| Color Capacity | 1-6 spot colors (each requires separate screen) |

| Print Resolution | 65-85 LPI (lines per inch) for halftones |

| Mesh Count Range | 110-230 threads per inch (TPI) |

| Ink Types | UV, Plastisol, Solvent-based, Water-based |

| Curing Temperature | 150-180°C (varies by ink type) |

| Production Speed | 500-1,500 buckets per hour (automated systems) |

| Setup Time | 3-7 days for screen preparation |

| Durability Rating | Excellent – 3-5 years outdoor exposure |

| Cost Per Screen | 1-6 spot colors (each requires a separate screen) |

✓ Advantages

- Cost-effective for large quantities

- Excellent durability and color vibrancy

- Works well on curved surfaces

- Wide range of ink options

✗ Limitations

- High setup costs for small runs

- Limited to spot colors

- Color changes require new screens

- Not ideal for complex gradients

Summary: When to Choose Screen Printing

Screen printing is the optimal choice for plastic bucket decoration when you need:

- High-Volume Production: Orders of 1,000+ units where per-unit cost efficiency is critical

- Maximum Durability: Prints that must withstand harsh chemicals, outdoor exposure, or frequent handling

- Brilliant Color Vibrancy: Opaque, vivid colors that maintain appearance over extended product lifecycles

- Simple to Moderate Designs: Logos, text, and graphics with 1-4 spot colors

- Consistent Repeat Orders: Established products with fixed designs that justify setup investment

- Chemical Resistance: Applications involving industrial chemicals, cleaning agents, or harsh environments

- Cost Efficiency at Scale: Long production runs where amortized setup costs yield the lowest per-unit pricing

With proper technique, equipment, and quality control, screen printing delivers unmatched value for medium to high-volume plastic bucket printing applications, combining durability, aesthetics, and economics in a proven, reliable process.